Future Trends in Plastic Slide Innovation for Industry 2025

As we navigate through the rapidly evolving landscape of industrial design and manufacturing, the significance of innovative materials cannot be overstated. Among these, the Plastic Slide has emerged as a pivotal component, embodying the intersection of functionality and technological advancement. By 2025, we anticipate a series of transformative trends in Plastic Slide innovation that will redefine their application across various industries. This blog will explore the digital integration within Plastic Slide technology, offering compelling reasons why companies must adopt these advancements to enhance efficiency and sustainability. From enhanced durability and cost-effectiveness to superior design flexibility, the potential for Plastic Slides to revolutionize industrial operations is immense. Join us as we delve into the future trends that promise to reshape the role of Plastic Slides in manufacturing and beyond.

Emerging Technologies Shaping Plastic Slide Manufacturing by 2025

As we look towards 2025, the landscape of plastic slide manufacturing is on the brink of transformation due to emerging technologies. Innovations in 3D printing and advanced materials are paving the way for greater customization and sustainability in production processes. Companies are increasingly adopting biodegradable plastics and recycled materials, addressing the growing environmental concerns associated with traditional manufacturing methods. This shift not only enhances the ecological footprint of plastic slides but also appeals to a more environmentally conscious consumer base.

Tip: Consider incorporating additive manufacturing techniques. By using 3D printing, manufacturers can produce complex designs with reduced waste and shorter lead times, which is a significant advantage in today’s competitive market.

Furthermore, smart technologies, such as IoT-enabled manufacturing, are set to revolutionize quality control and operational efficiency. Sensors integrated into production lines can monitor conditions in real-time, allowing for immediate adjustments and enhancing overall quality. This technology not only improves product reliability but also streamlines processes, reducing downtime and costs.

Tip: Evaluate the integration of IoT in your manufacturing processes. Implementing smart factory solutions can significantly increase productivity and provide insights that lead to continuous improvement in your operations.

Sustainability: The Future of Eco-Friendly Plastic Slides in Industry

As industries increasingly prioritize sustainability, the innovation of eco-friendly plastic slides is set to revolutionize play and leisure environments. A recent report from the Plastic Pollution Coalition highlights that the global market for biodegradable plastics is projected to reach $20.2 billion by 2025, reflecting a growing shift toward eco-conscious materials. This trend paves the way for new types of plastic slides made from sustainable resources, reducing the environmental impact while maintaining safety and durability.

Incorporating recycled materials into the production of plastic slides not only minimizes waste but also meets the rising consumer demand for sustainable products. According to the Ellen MacArthur Foundation, transitioning to circular economy practices can generate economic benefits of $1 trillion by 2025 for the plastics industry. By focusing on design innovations that utilize post-consumer recycled plastics, manufacturers can create slides that not only serve their functional purpose but also contribute to a cleaner planet. As these trends continue to gain momentum, the blueprint for the future of plastic slides in industrial applications becomes not just about play but also about responsibility and environmental stewardship.

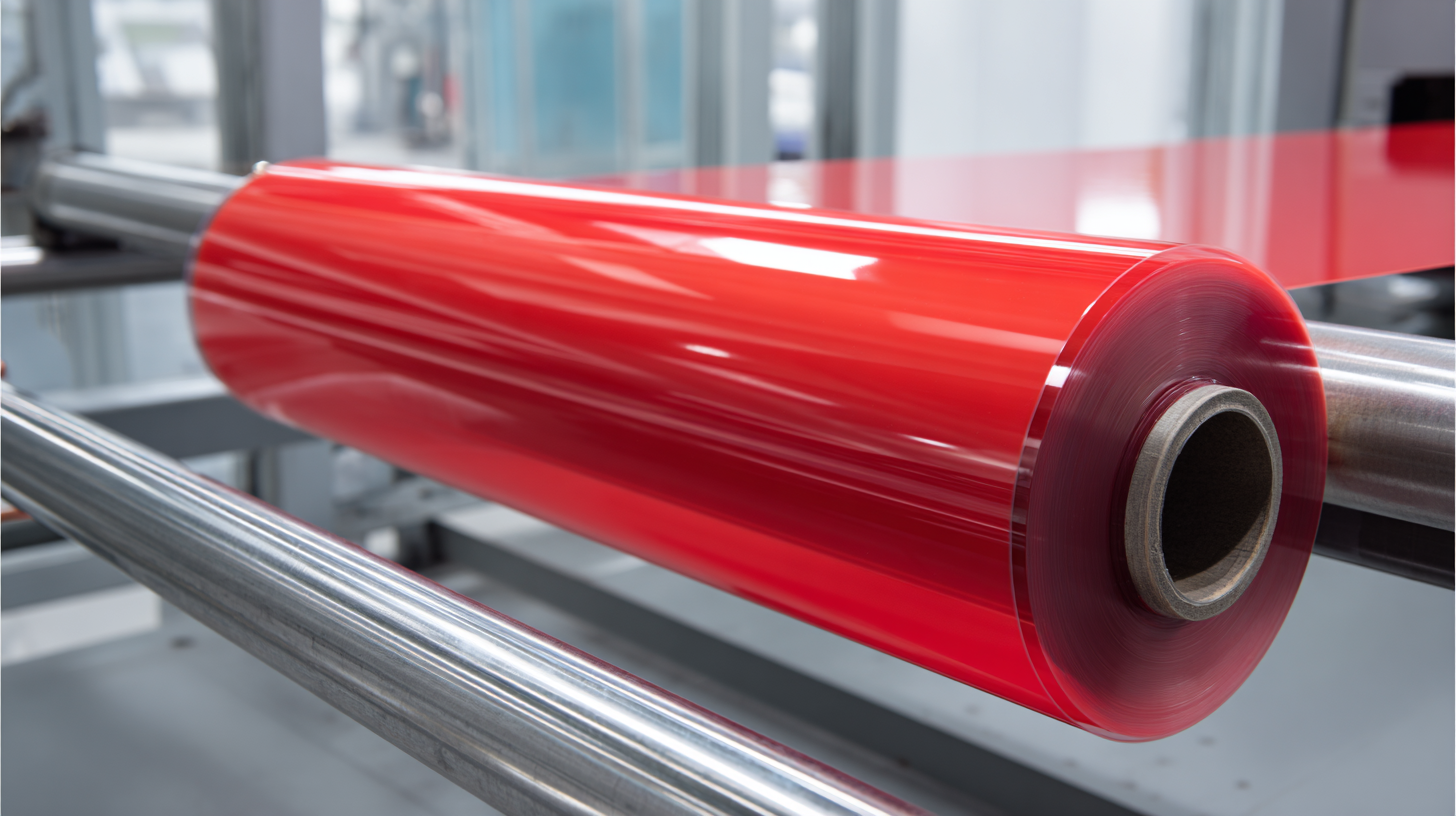

Innovative Materials: Next-Generation Plastics for Enhanced Performance

The evolution of plastic materials is set to revolutionize various industries by 2025, particularly in the realm of plastic slide innovation. A recent report by MarketsandMarkets predicts that the global plastic market is expected to reach $1 trillion by 2025, fueled by the growing demand for lightweight, durable materials in sectors such as automotive, aerospace, and consumer goods. Among these advancements, next-generation plastics like bio-based polymers and high-performance thermoplastics are gaining prominence, offering unique properties that enhance functionality and sustainability.

Innovative materials are at the forefront of this transformation. For instance, bio-based plastics derived from renewable resources are anticipated to account for over 20% of new plastic materials produced by 2025, according to a report from Grand View Research. These materials not only reduce dependency on fossil fuels but also provide improvements in biodegradability and lower environmental impact. Furthermore, high-performance thermoplastics, such as polyether ether ketone (PEEK), are emerging as viable alternatives in demanding applications, boasting superior thermal stability and chemical resistance. Such progress in material science is poised to drive efficiency and performance in manufacturing processes, unlocking new possibilities for product design and functionality in the years to come.

Automation and Smart Manufacturing in Plastic Slide Production

The upcoming trends in plastic slide production are significantly influenced by automation and smart manufacturing, which are transforming the industry landscape as we approach 2025. With the global linear slides market estimated at USD 2.73 billion in 2023 and projected to experience a compound annual growth rate (CAGR) of 6.6% from 2024 to 2030, the demand for innovative and efficient production processes is higher than ever. This growth indicates a robust opportunity for manufacturers to embrace cutting-edge technologies that enhance the precision and efficiency of their operations.

The integration of advanced manufacturing technologies, including artificial intelligence, is set to redefine traditional production methods. By leveraging these technologies, manufacturers can streamline processes, reduce costs, and improve quality control. This shift toward smart manufacturing not only prepares companies for the anticipated Manufacturing 4.0 era but also enables them to meet the rising demands of the linear slide market with greater agility and responsiveness. As automation becomes more prevalent, the emphasis on adaptable and scalable production solutions will be paramount for success in this evolving industry.

Future Trends in Plastic Slide Innovation for Industry 2025 - Automation and Smart Manufacturing in Plastic Slide Production

| Trend | Impact on Production | Expected Adoption Rate (%) | Key Technologies |

|---|---|---|---|

| Automation Integration | Increased efficiency and reduced labor costs | 75 | Robotics, AI |

| Advanced Material Usage | Improved durability and performance of slides | 65 | Smart Plastics, Biodegradable Polymers |

| Smart Manufacturing | Real-time monitoring and predictive maintenance | 70 | IoT, Big Data Analytics |

| Sustainable Production Practices | Reduced environmental footprint and cost savings | 80 | Recycling Technologies, Green Energy |

| Customization and Personalization | Increased consumer satisfaction and product differentiation | 60 | 3D Printing, Digital Twins |

Global Market Trends: China’s Role in the Evolution of Plastic Slides

As we venture into the future of plastic slide innovation, it is crucial to recognize China's pivotal role in shaping global market trends. With its robust manufacturing capabilities and a rapidly expanding economy, China is poised to become a leader in the production and design of plastic slides. Innovations stemming from this region are not only enhancing the functionality and durability of these products but also making them more environmentally friendly through the use of sustainable materials and practices.

China's influence extends beyond mere production; it is also a hub for research and development in plastic slide technology. Local companies are investing heavily in R&D to develop advanced materials that can withstand greater stress while being lightweight. This trend is driving the evolution of plastic slides, catering to diverse industrial applications, ranging from playgrounds to commercial environments. As the global demand for innovative plastic solutions increases, China's strategic focus on innovation will undoubtedly play a crucial role in the industry's trajectory leading up to 2025 and beyond.